An Industry Partner

We're fully equipped with high-performance machinery that allows us to produce high-volume runs. Our global footprint allows us to deliver to clients all around the world. We're constantly working with our clients to develop new technologies and processes. We run manufacturing and R&D centers in the most important automotive markets across the globe, making us a critical component of the production line.

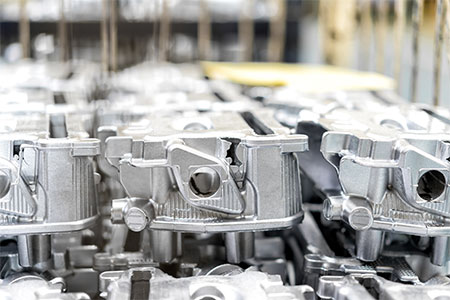

Critical Applications for OEMs

We provide lightweight, high-quality solutions to the automotive industry. As a full-service manufacturer, our capabilities include mold design, prototyping, plastic injection molding, semi-solid die casting, testing and validation, and mold repairs. Our tooling capabilities are elevated thanks to our state-of-the-art technologies. When it comes to end-of-arm tooling, gages and fixtures, and bezels, you need a partner you can rely on. Our product development and overall production cannot be matched.

Silver Basis Engineering is a well-recognized and award-winning automotive parts manufacturer with eight manufacturing plants, multiple sales and service locations, over 511 patents, and numerous automotive accreditations and certifications.