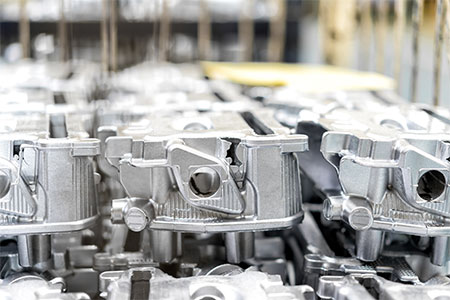

Prototype & Production Capabilities

Semi-sold casting using a high-viscosity feed that is half liquid and half solid. There are many advantages to semi-solid die casting. These benefits include but are not limited to lighter parts, tighter tolerances, greater pressure tightness, excellent overall mechanical performance, reduced shrinkage, thinner walls and the ability to be heat treatable. This process allows us to produce complex parts that are porosity free. The production capabilities are truly endless.